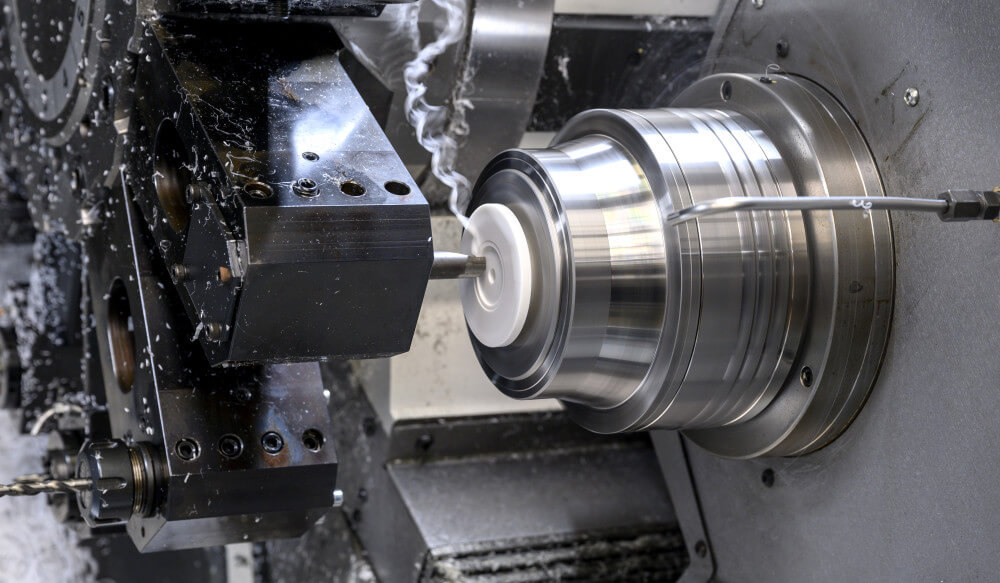

Mannes Westhuis welcomes us warmly in Werkendam and introduces us to Sonja and Johan van Anrooy, the founders of ANKRO, who are still involved in 'their' company. We take a quick walk through the production hall; here everyone is busy machining plastics. What is that exactly? Mannes: "It's a kind of sculpting with a block of plastic, which is clamped down and a spindle rotates around it. By means of lathes, you remove everything from a block of plastic that you don't use. With a turning mill, you can make even more complex products. We make plastic parts that are needed in all kinds of machines. Sometimes a support block, sometimes a product with a complex shape."

How did ANKRO come into contact with BKB Precision? "I was called by an intermediary: this is a nice company, you should take a look," Mannes says. "And I just said: not now, I was busy with investments. A little later he called a second time, then I said no again. In November 2021 I was called again. We then made an appointment to talk to Sonja and Johan. Then it starts to bubble. I really believe that one plus one equals three. You have a sister company that you click with, you can grow together. You take steps together, see if you can add something to it. Then it becomes even more beautiful. Smart planning is then important. But everyone wants to make a success of it. I would really like to look back in five or seven years and say that it has become more than three."

Mannes: "In this marriage, the main intention is that we learn from each other, especially on a technical level. For our customers, we add capacity and capability. We all want to make the most beautiful product at the best price. What also matters is that professionals speak the same language. And we are Brabanders among ourselves, that goes very well. BKB Precision recently turned 40, we immediately invited them to the party."

Mannes is a lawyer by training. "But business development is much more fun. We are going to work on efficiency and automation here to optimize our inventory management and install new machines. Economies of scale are something that is demanded. A company that grows offers many opportunities. Also for the employees, who want to grow in their role. If you are at the top of the supply chain, people want continuity. We see that the number of foreign customers is also increasing; they often find that Dutch companies are creative. But as I said, we are going to work on this hall first. In the long term, we may be able to develop the land next to it. Now we are focusing on embedding production, so that we can talk to each other as sisters. This applies to tools or plastics: is that one piece perhaps in Werkendam? Or for personnel: do we have too few hands here, get on the bus in Son and come and help here."

The CEO does not forget where the company comes from. "Johan and Sonja have put their heart and soul into this company. It is getting bigger, it is getting more formal. ISO has to be implemented at one point, you have to start describing things. The production control must remain as flat as possible, but reporting lines now have to be set up, people will really have to take their leadership positions."

The higher energy prices are also a cause for concern for Mannes. "We are also confronted with an enormous cost increase, the continuity of the company is important. This energy crisis is also putting employers and employees a bit against each other. That's a shame. These are really things that happen to us and that you don't see coming, just like the corona crisis and the repayment obligation at a time when costs are rising. But we need heat for extrusion. By heating granulate you make a very compact material. There are already metal companies that say: I can't pay for it anymore. A crying shame! That also affects us: if there is no metal, no appliances are built and no plastic products can be made."

The energy crisis is therefore also leading to a tightened policy at the Werkendam company. Mannes: "Everything is getting sharper, you have to sail with the wind and make choices. You have to be able to explain those choices, otherwise you will encounter incomprehension and unwillingness."

Despite this, Mannes is optimistic about the future. "The manufacturing industry has picked up considerably thanks to the government's attention. This manufacturing industry in combination with knowledge can really deliver beautiful products. Now we can also exchange knowledge with each other as ANKRO and BKB Precision. ANKRO was already quite well-known in the region, but definitely has national, even international potential. If you are a good niche player, a German customer, for example, will find that interesting. It's really like this: if you get body, you can hook on a bit more.