Please feel free to contact us. You can do so by phone at +31 (0)183 304 872 or by filling out the contact form. We will handle your question as soon as possible.

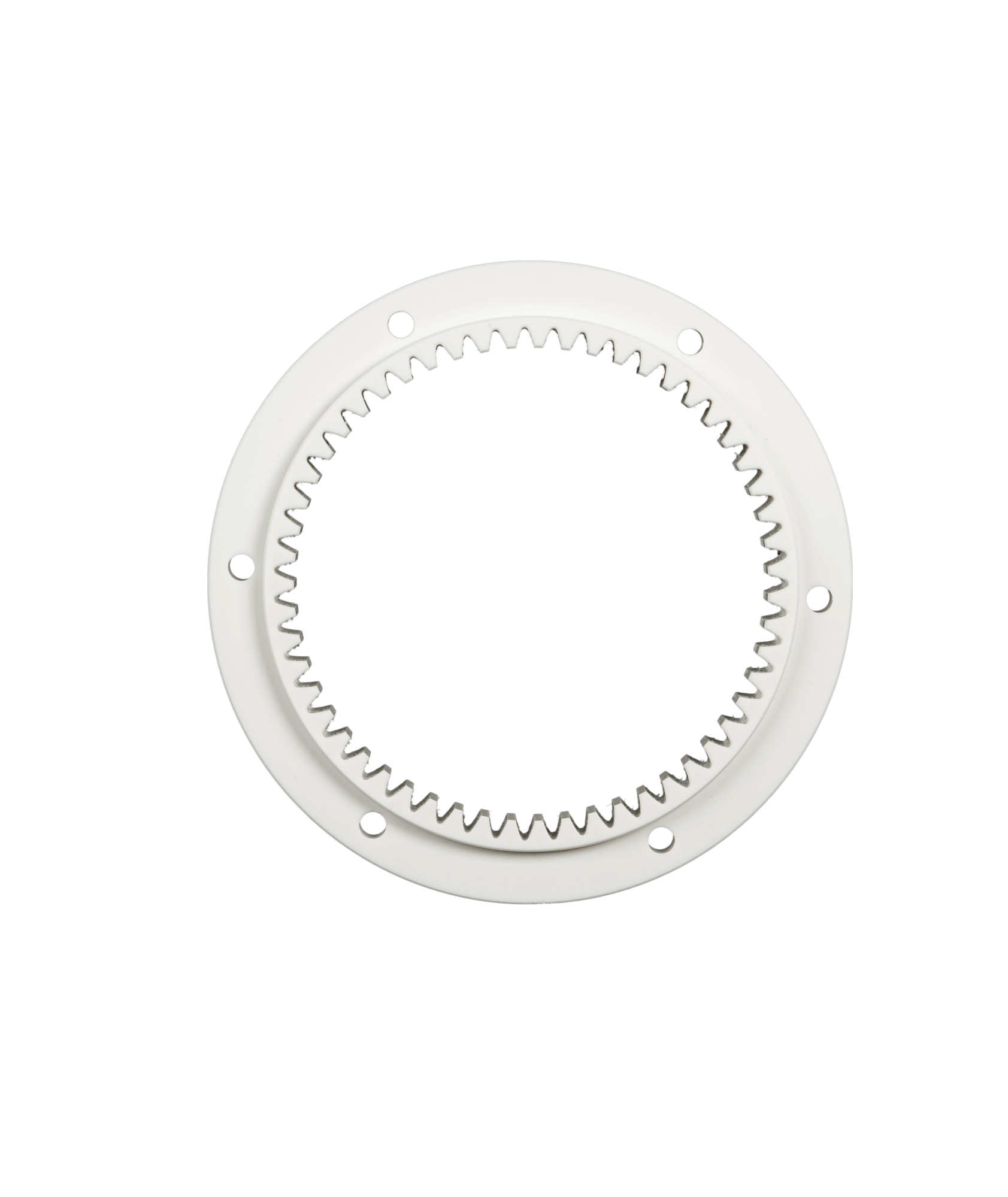

Plastic gears offer a reliable and durable solution in many machines and systems. Due to their silent operation low maintenance requirements and dimensional stability they are suitable for a wide range of applications.

At ANKRO plastic gears are fully custom made from single pieces to large series. Thanks to our expertise we deliver not only precise toothing and a perfect fit but also advise on the right material selection.

Custom plastic gears from ANKRO mean more than just production it is the result of a precise process where innovation and craftsmanship come together. With our modern machinery we apply various machining techniques such as milling, turning and turn milling to produce the detailed tooth profiles and the round and symmetrical parts.

Thanks to this combination of techniques we can deliver high quality plastic gears ranging from single pieces to larger series. Always with the quality and precision your projects deserve.

Custom plastic gears combine technical features with practical advantages making them widely applicable across various industries. They offer excellent performance in terms of wear resistance and noise reduction while being low maintenance and cost efficient. Additionally they are lightweight and corrosion resistant making them an attractive alternative to metal gears. Other key advantages may include:

Plastic gears are used in a wide range of sectors including mechanical engineering automation electronics automotive and medical technology. You will find them in conveyor drives printers ventilation systems medical pumps household appliances robots and much more. Thanks to properties like low weight dimensional stability and chemical resistance they are suitable for both simple and demanding applications.

Whether it concerns small precise gears for fine mechanics or robust designs for industrial drives almost any combination of size toothing and material is possible. Curious how ANKRO can help with that?

The choice of the right material determines the performance and lifespan of a plastic gear. Depending on the application we select plastics with specific properties such as wear resistance strength or chemical resistance. Commonly used materials include POM polyoxymethylene for its low coefficient of friction and dimensional stability and PA6 PA66 polyamide for high impact resistance and good mechanical strength.

Additionally PET, PE-HD and PTFE are suitable for situations requiring low friction chemical resistance or FDA compliance. Depending on technical requirements we are happy to advise which material best suits your application.

At ANKRO quality is central to every part of the process from design to final inspection. We produce plastic gears with high precision and work according to established procedures to ensure consistent dimensions and reliability. ANKRO is ISO 9001 certified and thus complies with international quality standards.

Want to know more about our quality approach View our quality page now!

Plastic gears offer many possibilities for those looking for customization durability and precision. Curious about what ANKRO can do for your application Feel free to contact us for advice a technical question or a non binding quote.

Please feel free to contact us. You can do so by phone at +31 (0)183 304 872 or by filling out the contact form. We will handle your question as soon as possible.