Ensuring quality through automated deburring

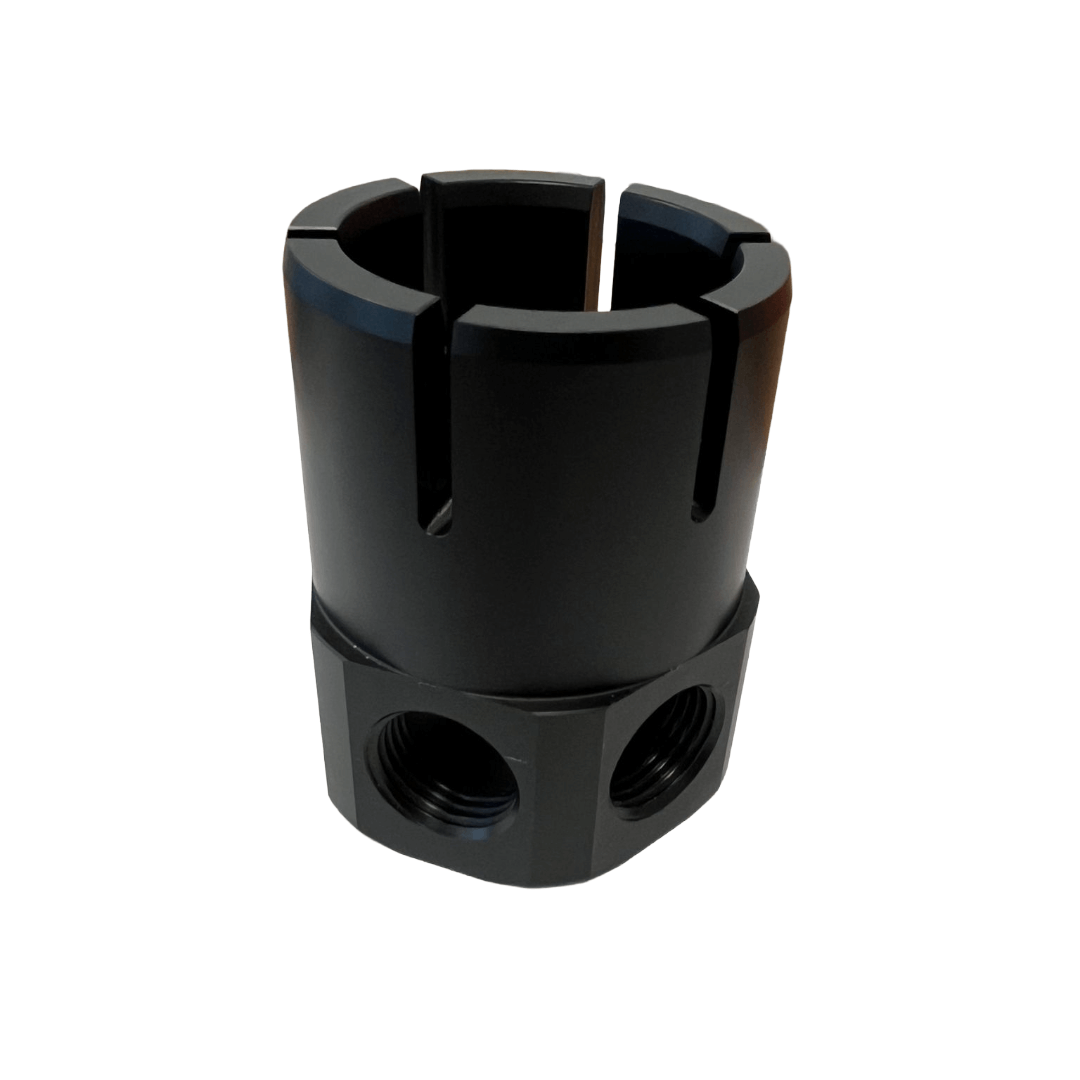

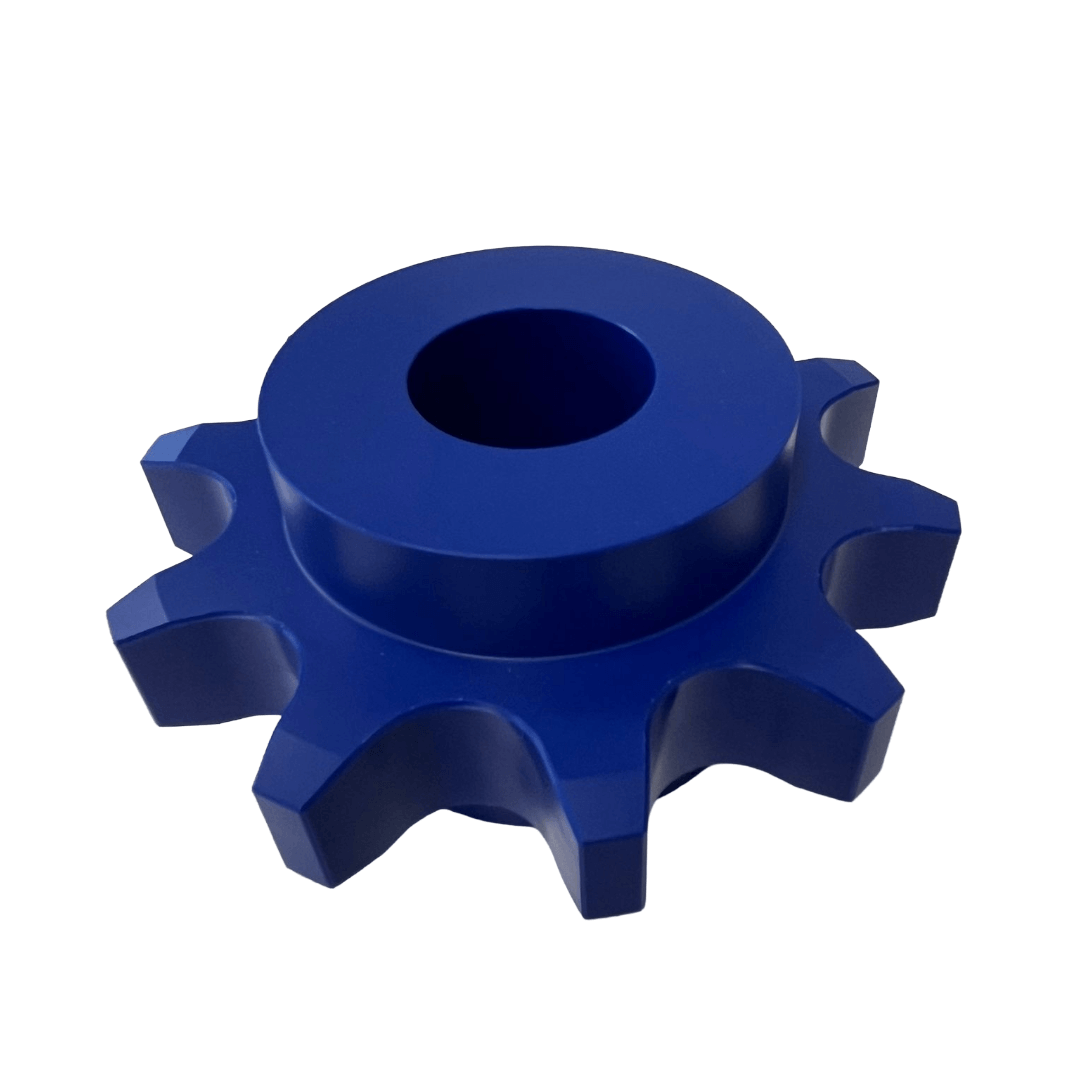

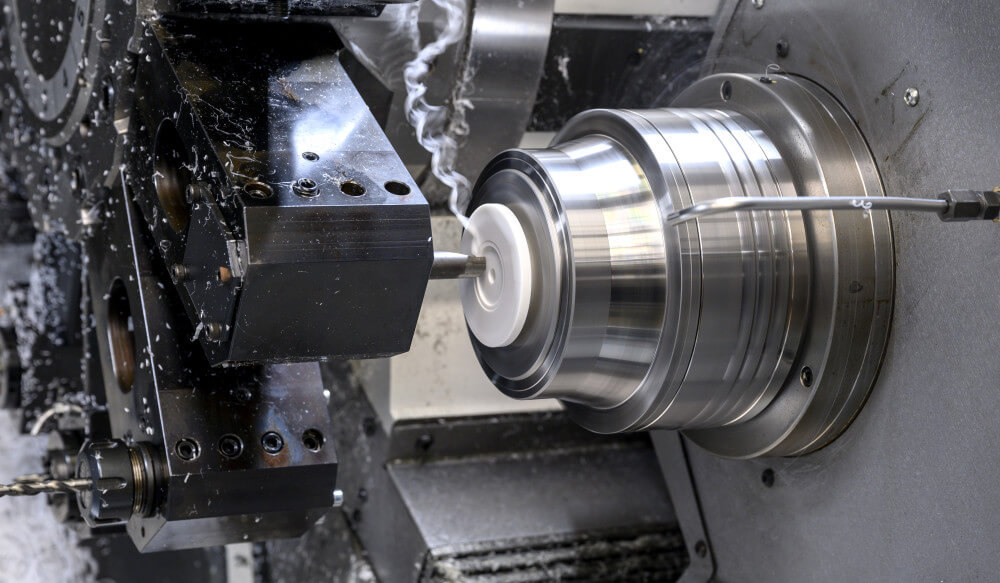

The machining of plastic parts often results in small burrs: sharp edges, unevenness, or excess material that remains after milling and/or turning. Although these irregularities may seem minor at first glance, they can have a major impact on the functionality, fit, and appearance of a product.

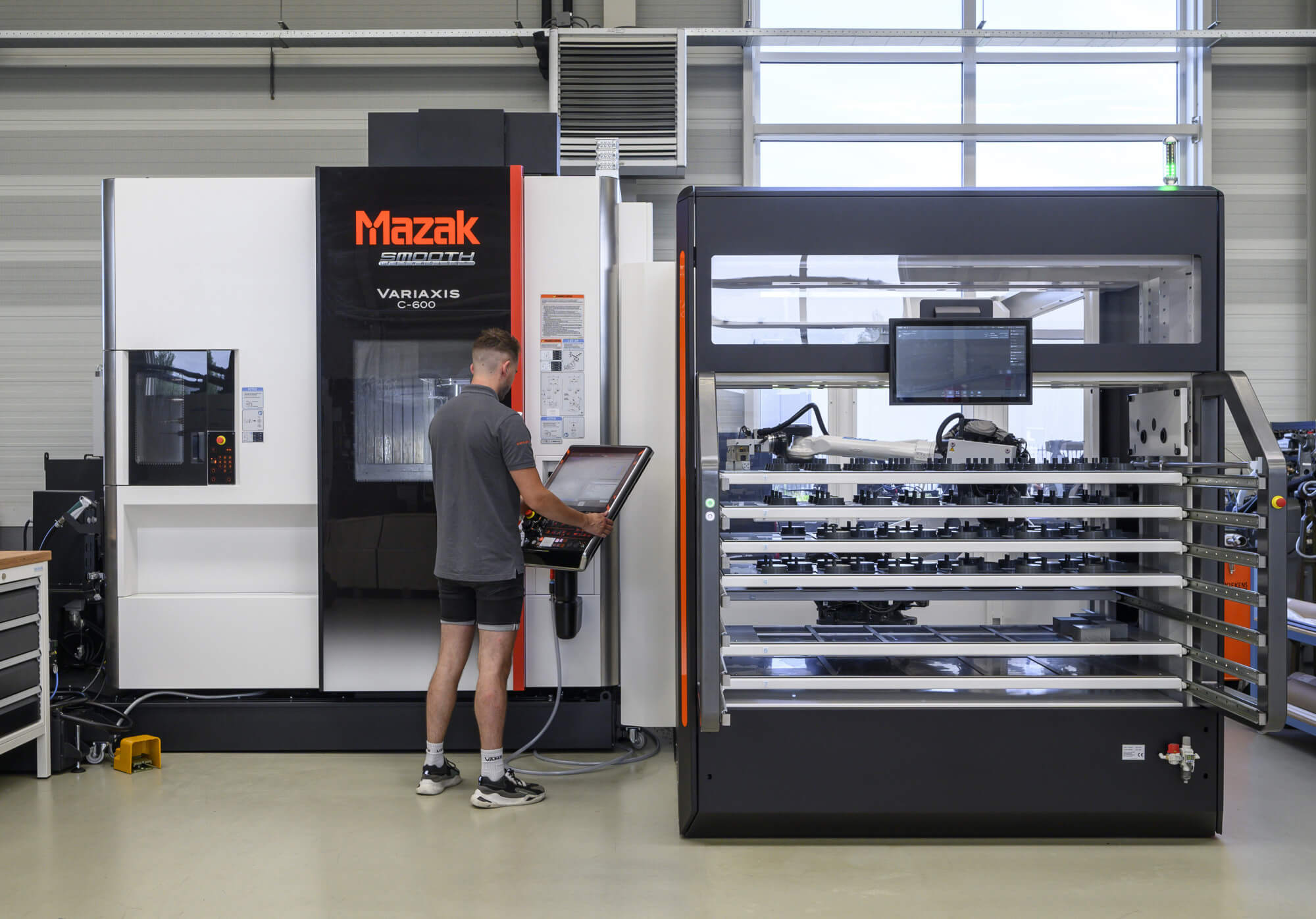

This makes deburring an important process for guaranteeing the quality, safety, and service life of plastic products. Whereas this used to be done manually or was not possible at all due to the complexity of the product, we have now fully automated this production step. From now on, we can deburr in previously impossible places (e.g., in channels). The end result is that we can guarantee consistently high quality and a more efficient production process.